Grease cartidge (chain type)

Grease cartidge (chain type)

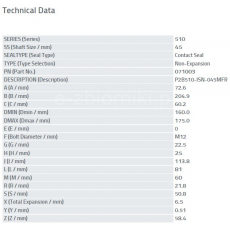

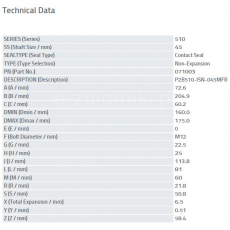

Technical parameters

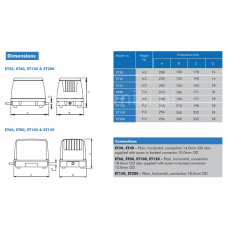

This is a pre-charged autogreaser which fits onto the chain guard to supply grease to the drive chain on BioDisc units BD, BE and BF. It is one of the most effective alternatives to manual lubrication.

The grease cartridge has 7 different settings allowing you to set efficiently depending on your application. Operates under a wide temperature range and can be installed up to 5 metres away from the application. Has a pressure release valve notifying you when there is a blockage.

Can be used for the following applications:-

- Roller bearings

- Plain Bearings/Slides

- Linear Guides

- Gears

- Chains

Delivery

Most accessories will be delivered within 1-3 working days. Deliveries are made to parcel machines or to a designated address specified by the Customer.

In the event of non-availability of the Goods, the Shop will inform the Customer of the expected delivery time and, in the case of paid orders, the Customer has the option to cancel the order with a full refund.

For more information on delivery, see the "Delivery and Returns" tab: https://www.e-zbiorniki.pl/information/17-delivery-returns

How it works

What is a Greasomatic?

A self-ejecting canister of lubricant designed to screw into a grease nipple socket or other lubrication point, and discharge its content of 120 ml of lubricant in a controlled continuous flow, for a preselected period of between one month and twelve months. It is completely self-contained and needs no pumps, motors, electricity or compressed air. Once fitted and activated, it will work without attention until its allotted lifespan is over.

How It Works

Each GREASOMATIC contains its own unique chemical expulsion unit. This has no springs or mechanisms but relies on an unvarying law of nature. Built into the top of each GREASOMATIC is a flexible rubber expansion chamber containing a liquid electrolyte and a galvanic element. The unit is activated by injecting the galvanic element into the electrolyte. The resultant electrochemical reaction generates a steadily increasing amount of gas, which gradually expands against a piston, to extrude the lubricant slowly but surely into the bearing to which the GREASOMATIC is fitted. The chemicals and gas remain hermetically sealed within the expansion chamber so that no contamination of the lubricant can occur, even after the unit itself is spent. During the working life of the GREASOMATIC, an indicating ring on the ejection piston shows through translucent windows in the body to enable the discharge state to be monitored.

Grease cartidge (chain type) Specification

- Product Code: 0011096

- Medium: Water

- Type of sewage treatment plant: BioDisc® BD

- Warranty: 2 years